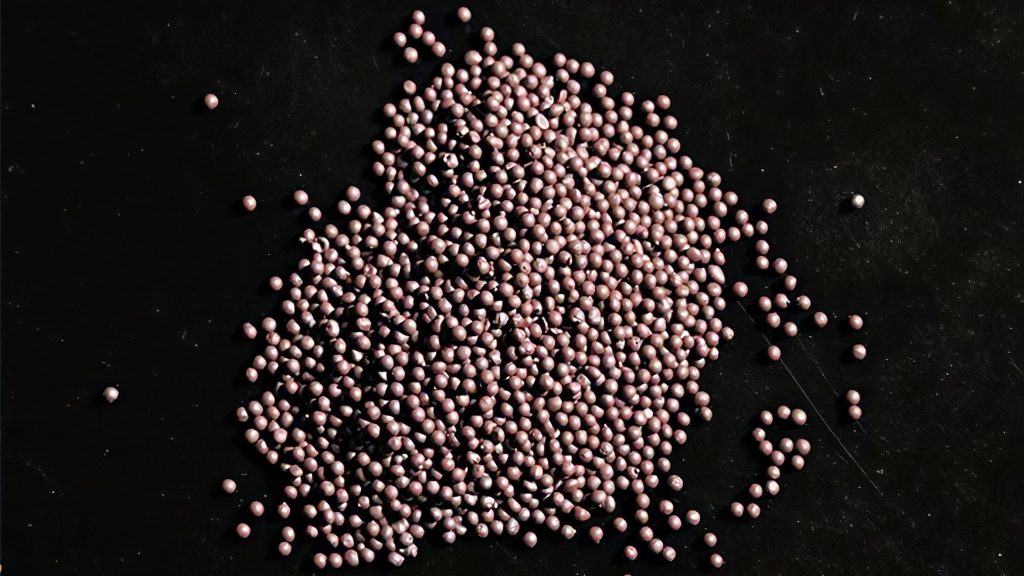

Low carbon steel shots contain less carbon, phosphorus and sulfur than high carbon steel shots. Therefore, the internal micro structure of low carbon shots are much smoother. Low carbon steel shots are softer compared to high carbon steel shots too. This results in 20 – 40 % longer abrasive life time.

Applications:

Typical application areas: pre-treatment of steel or cast-iron surfaces before painting, descaling and rust removal, deburring.

Advantages:

· Ideal for use to provide clean, polished metal surface.

· Low carbon steel shots are used in both turbine and compressed air blasting systems. Low carbon steel shots ensure lower turbine blades wear.

· Low carbon steel shots life cycle is about 30% longer than conventional high carbon steel shots.

· Shot blasting process produces less dust, that results in lower maintenance costs of filtration system.

Physical properties:

Hardness: 380 – 440 HV

Specific density: ≥ 7.2 g/cm³

Bulk density: 4,35 – 4,55 kg/dm³

Shape: round

Storage conditions: dry and covered

Packing: 25 kg bags, 1 ton per pallet

Chemical composition:

Fe: > 98 %

C: 0,1- 0,2 %

Si: 0,10 – 0,25 %

Mn: 1,4 – 1,5 %

S: 0,035 %

P: < 0,035 %